Precision machining is quickly acclimated style components, instruments, custom clasps, and different essential equipment. Subsequently, the parts should have the following capacity to bear the right coordination with different components.

The intriguing truth is that precision machining keeps up with responsibility for large-scale manufacturing components. this is many times altogether found in manufacturing fittings. precision machine parts producers guarantee steady and reliable results.

Besides, Precision Machining Components is discernible inside the culmination of metal items. For example, you’ll utilize precision machining using passing on projecting or less exact manufacturing methods to finish made parts. In actuality, precision machining has its purposes in Rebuilding work.

Likewise, worn components might require cutting, welding, or normalization at stretches for a period, In this manner, PC-helped instrumentation can reestablish the parts to their unique state.

Why pick precision machine components for your Task?

There are a few explanations behind choosing precision machining because it is the best strategy for worldwide creation.

We should head over with the advantages of precision machining:

- Most elevated precision level

The little millimeter will create an impression in world manufacturing explicitly inside the clinical regular way of thinking industry. on account of this explanation, precision machining is the greatest amount of need in the business. Each maker needs exact determinations and drawing and in this manner, the readiness of CNC machines conducts the right cuttings.

- Less Stuff wastage

However precision machining has ablative manufacturing, which creates a ton of material waste than added substance manufacturing, it brings down the mistake rate and constructs quality. This lessens the wastage of terrible quality items, or tedious techniques and uses more material.

Additionally, the Precision Machining Components prevailed in moving down unrefined substance wastage because the cut components bring pleasant exactness. we tend to know that unrefined components like graphite, copper, steel, and plastics are costly, and any waste isn’t very OK.

- Quick Get Together

The precision machines happened upon the components precisely and there’s no manual interference for getting together. since the technique is speedy and programmed, the gathering time is radically cut back.

- Proficient

With fewer mistakes and creating preeminent results, precision machining will brightly diminish the delivery cost. It grants creators to have the right budget report for the creation and decreases work uses.

- Safe Creation

Mishaps are the chief normal calculation manufacturing. According to the U.S. Work of Measurements, there have been 303 significant work wounds inside the manufacturing business. Machinery mishaps are upsetting, but on account of the programmed method of precision machining cut back their event.

- Useful and Fast Creation

Since the PCs are the board precision machined components and have each detail of creation programs, they’re powerful and expedient in producing the results.

- No Manual Association

With the utilization of precision machined components, there’s no propensity for human botches, that outcome in competent outcomes.

- Intentional Model Delivering

The preeminent essential beneficial thing about machining is that it will create models like end-use components. this recommends that CNC machining licenses the client to model their item abuse the end-utilize material. Further, it perseveres through testing for the norm and practicableness of the plan.

Through model machining, architects and fashioners can fix the issues. related to that, they will feature to the customers the reasonableness of a definitive item.

- Zero Blunders

The programmed precision machining strategy starts when the particulars are known. There are nada blunders contrasted with human machining. all through reevaluating, you wish not to enroll and lease prepared representatives to work these machines.

What Components will Schildthorn Hold Insight in?

- Edge Components

We offer you superior execution vertical and level edge places for your machined components double-dealing productive strategies. From very duplex, and titanium, to aluminum and clean steel, we will quite often cowl every one of the materials. Also, our machines fitted with WIPS inquisitory and optical gadget apparatus breakage identification guarantee quality.

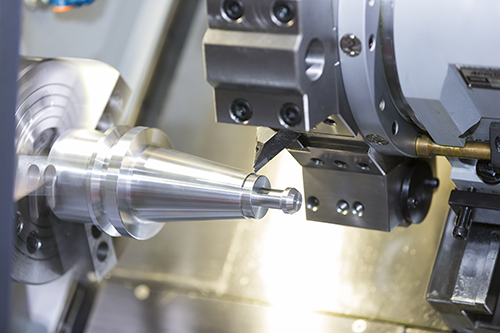

- Turning Components

Schilthorn gives Going components to steady execution that has high string uprightness, tight resilience, and sans burr edges for a fine completion. Our precision designing offices blend CNC Turning and go plant to concoct direct and confounded components for various areas.

- SPM Components

to build up the norm of the product and convey top-notch components in mass, we tend to make a progression of Specific Reason Machines. we will generally create specially designed machines that are suitable for the technique of turning, processing, and stringing.

Anyway, we help you with precision machined components?

Schilthorn fabricates precision machined components with pleasant exactness and optimal aspects for vital areas. Our stylish machinery, materials, and instrumentation satisfy the guidelines of the business.

On the contrary hand, our precision machining components and creating go from prototyping to creative ability. we tend to not exclusively convey precision designing components anyway also creative ways for your business enhancement:

Our first-class quality machines that suit your details are as per the following:

- Forming Machine

- Programmed forming machine THU

- Surface Processor

- Seat Processor

- Metal saw Machine

- Cutting machine

- Penetrating machine

- SPM Computerizes

- Opening Machine

- String Moving Machine

- Arrangement Press

- Tidying Machine

- Etching Machine

- HAAS Constructs Even edge Habitats

- HAAS makes Vertical edge Habitats

- HAAS make CNC two-pivot Turning Focuses

- Turn Mills